Change Language :

iglidur® L250 - Material data

Material table

General specification

Unit

iglidur® L250

Test method

density

g/cm³

1,50

Colour

beige

max. Moisture absorption at 23°C/50% room humidity.

% by weight

0,7

DIN 53495

max. total moisture absorption

wt.-%

3,9

Sliding friction coefficient, dynamic, against steel

μ

0,08-0,19

pv value, max. (dry)

MPa x m/s

0,4

Mechanical specification

flexural modulus

MPa

1.950

DIN 53457

flexural strength at 20°C

MPa

67

DIN 53452

Compressive strength

MPa

47

maximum recommended surface pressure (20°C)

MPa

45

Shore D hardness

68

DIN 53505

Physical and thermal specification

Upper long-term application temperature

°C

+90

upper short-term application temperature

°C

+180

Upper short-term ambient temperature1)

°C

+200

Lower application temperature

°C

-40

thermal conductivity

W/m x K

0,24

ASTM C 177

coefficient of thermal expansion (at 23°C)

K-1 x 10-5

10

DIN 53482

Electrical specification

Volume resistivity

Ωcm

> 1010

DIN IEC 93

surface resistance

Ω

> 1011

DIN 53482

- Without additional load; no sliding movement; relaxation not excluded

Table 01: Material data

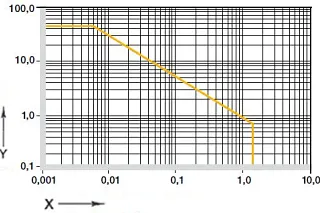

diagram. 01: Permissible pv value for iglidur® L250 plain bearings with 1 mm wall thickness in dry operation against a steel shaft, at +20 °C, installed in a steel housing

X = surface speed [m/s]

Y = load [MPa]

iglidur® L250 is a plain bearing material for high speed, fast sliding movements and low coefficient of friction. The material iglidur® L250 can utilise these advantages particularly at low loads. Applications in which these advantages play a role include fans, small motors, high-speed sensors and magnet technology.

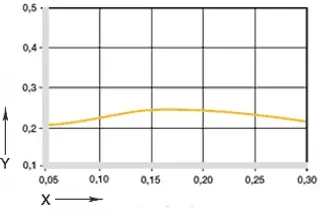

Diagram 04: Coefficient of friction as a function of the surface speed, p = 0.75MPa

X = surface speed [m/s]

Y = coefficient of friction μ

friction and wear

In the best pairing (against 304 SS shafts), a low load coefficient of friction of 0.14 is achieved. Even at 10 MPa coefficients of friction below 0.1 were measured (diagram. 04 and 05).

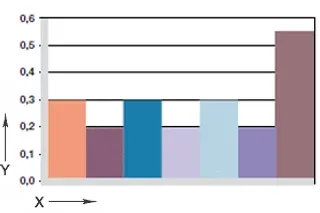

diagram. 06: Wear, rotating application with different shaft materials, p = 1 MPa, v = 0.3 m/s

X = Shaft material

Y = wear [μm/km]

A = aluminium, hard anodised

B = free cutting steel

C = Cf53

D = Cf53, hard chrome-plated

E = HR carbon steel

F = 304 SS

G = high grade steel

Shaft materials

As can be seen in diagram 06, a large number of shafts are recommended for low load and low rotation.

The good coefficients of friction are also maintained over a wide range of recommended shaft roughnesses. For loads greater than 1 MPa, special attention should be paid to the shaft material used.

Consulting

I look forward to answering your questions

J. & E. Papadopoulos S.A.+30 210 4113133Write e-mail

Shipping and consultation

In person:

Monday to Friday from 7 am - 17 pm.

Saturdays from 8 am- 12 pm.

Online:

24h

WhatsApp-Service:

Montag – Freitag: 8 – 16 Uhr