Change Language :

What is iglidur?

iglidur materials are developed by igus, made of high-performance polymers that are characterised by their special properties: Their special composition makes them extremely wear-resistant, robust and self-lubricating. Their service life can be precisely determined. In addition, each iglidur material has individual specifications and strengths that make it suitable for special applications.

What are iglidur materials made of?

All iglidur materials are made up of three components: base polymers, fibres and fillers, solid lubricants. As it is not possible for one universal material to fulfil all tasks equally well, there are different iglidur materials. Each has a different proportion of the three components and a different application area.

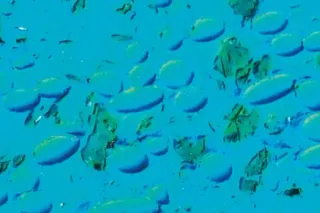

Base polymers with fibres and solid lubricants, magnified 200 times, coloured

How does the self-lubricating effect work?

The solid lubricants are embedded millions of times in tiny chambers in the solid, usually fibre-reinforced material. The material releases tiny amounts of the solid lubricants from these chambers. This is enough to sufficiently lubricate the immediate surroundings.

They also help to reduce the coefficient of friction of the iglidur materials. They are not indispensable for the function of the bearing, but they do have a supporting effect. As they are embedded in the tiny chambers, they cannot be pressed out.

Thanks to the self-lubricating effect, maintenance on iglidur materials can be minimised. Regular relubrication is not necessary due to the incorporated solid lubricants and dirt or dust cannot accumulate. This also contributes to sustainability.

Predictable service life

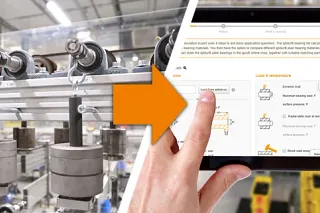

iglidur materials have been tested thousands of times in practical trials and proven millions of times in application. The test data from the trials are incorporated into the free igus online tool, which can be used to precisely predict the service life, e.g. plain bearings, bar stock and slewing ring bearings made from iglidur materials.

Specifications of our iglidur materials

Other plain bearing plastics and their specifications

POM

This material is easy to process and machine, which is why it is so versatile. POM plastic is also wear-resistant and comparatively inexpensive. However, it quickly reaches its limits at high temperatures and loads. POM also tends to emit small amounts of formaldehyde, which is why the material must not be used in vehicle interiors, for example. However, it is used, e.g. in hand mixers or packaging lines.

PA66

PA66 is also versatile and inexpensive, but in contrast to POM it is also significantly stronger and somewhat more temperature-resistant. However, this material is less easy to machine. PA66 is more wear-resistant than POM, has good friction behaviour and high mechanical strength. It is therefore often used for bearing points subject to higher stresses. The addition of fillers and reinforcing materials results in many different specifications and applications.

PEEK

It is often used for plain bearings and can be described as a high-end material. It can be used at temperatures above 200°C, is resistant to chemicals and has good strength and good tribological specifications. However, PEEK is comparatively expensive and can cost 20 times as much as POM or PA66. PEEK is often used where other plastics cannot withstand and metallic bearings can only be used with lubrication or protected against corrosion at great expense.

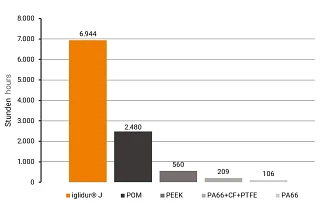

Wear test: how does iglidur perform compared to other plastics?

Test parameters:

- Rotation

- Speed v = 0.3m/s

- Load p = 1N/mm²

- Shaft material: 304 SS

Test results show that various base polymers exhibit very different service life. iglidur achieves a comparatively high value as a compound based on one of the base polymers tested.

White paper: iglidur compared to other plastics

Plain bearing materials put to the test: iglidur versus conventional plastics

The white paper covers the following topics, among others:

- How do I find the right plastic bearing?

- Which plain bearing materials are available and what characterises them?

- How do plain bearing materials compare with each other?

- What is the wear behaviour of the various plain bearing materials? (Test procedures, test results)

Consulting

I look forward to answering your questions

J. & E. Papadopoulos S.A.+30 210 4113133Write e-mail

Shipping and consultation

In person:

Monday to Friday from 7 am - 17 pm.

Saturdays from 8 am- 12 pm.

Online:

24h

WhatsApp-Service:

Montag – Freitag: 8 – 16 Uhr