Change Language :

Components for hygiene-sensitive areas in the food industry

Use of igus® products in the food industry

Selected motion plastic for the food industry

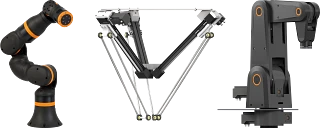

Cobots, delta pickers, gel arm robots and much more ...

Automation in the packaging industry

Automating processes with low complexity, fast integration into existing systems and a quick return on investment? That is the stated aim of our products from "Low Cost Automation".

Format adjustment in the packaging industry - from manual to smart positioning

Successful in use

Aggressive environmental conditions (cleaning, extreme temperatures, dust and dirt), high hygiene standards, long service life in continuous operation, fast and flexible format adjustments... The requirements in the packaging, food and beverage industries are diverse. Here you can find out more about the successful use of our motion plastic by our customers.

White paper: Kolsterising and tribopolymers

Especially in an industry that depends on precise and fast processing with maximum purity and economy, the combination of colsterisation and high-performance plastics should become the standard ...

Tested for real use in the test laboratory

iglidur® bearings and drylin® linear technology are put through their paces in the industry's largest plastic test laboratory. Among other things, they are tested for media resistance (e.g. cleaning media), continuous load and low-noise operation. The results are fed into our tools for calculating service life and enable precise predictions to be made about durability.

Upon request, igus® also carries out customer tests in order to test the use of the products under very individual conditions.

More information

The large sample box

With the igus® corner, you always have the right motion plastic for your industry at your fingertips.

igus® blogs

Topics and trends from the packaging industry. Discover them now in our blog.

Consulting

I look forward to answering your questions

J. & E. Papadopoulos S.A.+30 210 4113133Write e-mail

Shipping and consultation

In person:

Monday to Friday from 7 am - 17 pm.

Saturdays from 8 am- 12 pm.

Online:

24h

WhatsApp-Service:

Montag – Freitag: 8 – 16 Uhr