Change Language :

Low-clearance lead screw nuts

What should you do in the event of unwanted axial clearance?

What is axial clearance anyway?

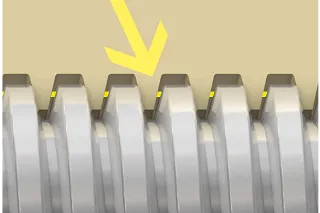

Yellow = Axial clearance

Axial clearance can be used to describe the lost motion, the "dead travel", on the lead screw as a result of the gap between the lead screw and the lead screw nut. The term clearance is also often associated with it, but the correct technical term is axial clearance. It is thus the movement of the lead screw nut in the axial direction without movement of the lead screw. Lead screw drives require a minimum clearance to maintain their function. If the axial clearance is too small, the torque required to move the lead screw nut will also increase.

Application-specific parameters must be observed in addition to the lead screw drive clearance caused by manufacturing tolerances. In addition to thermal and hygroscopic environmental influences, the minimum clearance to be considered in the application must also take into account the friction heat generated by the application. This plays a decisive role in connection with the expansion behaviour of the polymer material used. As the axial clearance in the system can change with temperature fluctuations.

What options does the igus product range offer in this case?

To reduce the unwanted axial clearance, in addition to the correct choice of material, a preload mechanism has proven to be an effective measure. There are four variants with pretension for our dryspin® high helix thread and trapezoidal threads: zero-backlash, low clearance, preload and AB lead screw nut. Here you will find all the advantages and assembly instructions for our clearance-reduced lead screw nuts.

For applications with high loads, high temperatures or in heavily polluted environments, a standard lead screw nut should always be used. The reason for this is that all three principles are cancelled out by high loads. For this reason, the maximum static axial loads are specified separately for each lead screw nut model.

The zero-backlash lead screw nut

One of the most precise solutions is the ZB lead screw nut. It consists of several components and is self-adjusting to the service life. It is particularly suitable for lead screw drives with high helix threads for quick adjustment of small loads. The clearance-free principle ensures minimum clearance over the entire service life. Ideal for precise positioning and feed movements in medical, laboratory and printing technology as well as in the wide range of life sciences. The lead screw nut consists of a support nut, a fixing collar with torsion spring, a friction disc and the axial element. The torsion spring is used to apply pretension to the thread system.

- Lifelong minimal axial backlash

- More precise positioning and infeed movements

- In dryspin high helix threads

- Flange lead screw nut

- Thread direction: RH

- Material: iglidur J

Zero-backlash: Technical data

170) The idling torque of the zero-backlash lead screw nut increases with service life. For calculating and designing purposes, it is recommended that max. idling torque is taken into account.

| Thread | Max. static axial F [N] | Max. idling torque (with spring)170) from [Nm] | Part number |

|---|---|---|---|

| Ds5x5 | 75 | 0.02 | DST-JFRM-ZB-0001-DS5X5 |

| Ds6.35x2.54 | 75 | 0.005-0.02 | DST-JFRM-ZB-0001-DS6.35X2.54 |

| Ds6.35x5.08 | 75 | 0.005-0.02 | DST-JFRM-ZB-0001-DS6.35X5.08 |

| Ds6.35x12.7 | 75 | 0.005-0.02 | DST-JFRM-ZB-0001-DS6.35X12.7 |

| Ds6.35x25.4 | 75 | 0.005-0.02 | DST-JFRM-ZB-0001-DS6.35X25.4 |

| Ds8x10 | 150 | 0.01-0.03 | DST-JFRM-ZB-0001-DS8X10 |

| Ds8x15 | 150 | 0.01-0.03 | DST-JFRM-ZB-0001-DS8X15 |

| Ds8x24 | 150 | 0.01-0.03 | DST-JFRM-ZB-0001-DS8X24 |

| Ds10x12 | 150 | 0.01-0.04 | DST-JFRM-ZB-0001-DS10X12 |

| Ds10x25 | 150 | 0.01-0.04 | DST-JFRM-ZB-0001-DS10X25 |

| Ds10x50 | 150 | 0.01-0.04 | DST-JFRM-ZB-0001-DS10X50 |

| Ds12x3 | 500 | 0.08 | DST-JFRM-ZB-0001-DS12X3 |

| Ds12x5 | 500 | 0.08 | DST-JFRM-ZB-0001-DS12X5 |

| Ds12.7x12.7 | 500 | 0.08 | DST-JFRM-ZB-0001-DS12.7X12.7 |

| Ds12x15 | 500 | 0.08 | DST-JFRM-ZB-0001-DS12X15 |

| Ds12x25 | 500 | 0.08 | DST-JFRM-ZB-0001-DS12X25 |

| Ds14x4 | 500 | 0.08 | DST-JFRM-ZB-0001-DS14X4 |

| Ds14x25 | 500 | 0.08 | DST-JFRM-ZB-0001-DS14X25 |

| Ds14x30 | 500 | 0.08 | DST-JFRM-ZB-0001-DS14X30 |

The pre-load lead screw nut

The pre-load lead screw nut convinces with minimal axial clearance and highest positioning accuracy. It is the cost-effective alternative to the zero-backlash and perfectly suited for small pitches. This is the proven pre-load principle from SHT-PL. Typical application areas include 3D printers.

- For high helix threads up to a thread diameter of 6.35mm

- Cylindrical lead screw nut with flange

- Thread direction: right-hand thread

- Material: iglidur J

Preload lead screw nut: Technical data

| Thread | Max. static axial F [N] | max. idling torque (with spring) from [Nm] | Part number |

|---|---|---|---|

| Ds6.35x1 | 30 | 0.10 | DST-JFRM-PL-0001-DS6.35X1 |

| Ds6.35x2.54 | 30 | 0.10 | DST-JFRM-PL-0001-DS6.35X2.54 |

| Ds6.35x5.08 | 30 | 0.10 | DST-JFRM-PL-0001-DS6.35X5.08 |

| Ds6.35x6.35 | 30 | 0.10 | DST-JFRM-PL-0001-DS6.35X6.35 |

| Ds10x2 | 40 | 0.10 | DST-JFRM-PL-0001-DS10X2 |

| Ds10x3 | 40 | 0.10 | DST-JFRM-PL-0001-DS10X3 |

| Ds10x12 | 35 | 0.15 | DST-JFRM-PL-0001-DS10X12 |

The low-clearance lead screw nut

Our LC lead screw nuts are all equipped with two elastomer O-rings. The functional principle is similar to the AB lead screw nut. However, with the help of the LC lead screw nut, a reduction in clearance can be achieved in this case. The O-rings apply a circumferential radial pretension in the thread system, pressing the flanks of the lead screw nut and the threads of the lead screw. This ensures a constant axial and radial pretension of the nut. The high operational smoothness and cost-effective purchase are further advantages of the LC lead screw nut.

- Reduced axial clearance due to circumferential radial pretension

- Very quiet operation due to reduction of possible vibrations

- Cost-effective alternative to the zero-backlash nut

- In dryspin high helix and trapezoidal thread up to thread diameter 14mm

- Flange lead screw nut

- Thread direction: RH

- Material: iglidur J

Low-clearance lead screw nut: Technical data

dryspin high helix thread

| Thread | Max. static axial F [N] | max. idling torque (with O-ring) from [Nm] | Part number |

|---|---|---|---|

| Ds6.35x2.54 | 40 | 0.005 | DST-JFRM-LC-0001-DS6.35X2.54 |

| Ds6.35x5.08 | 40 | 0.005 | DST-JFRM-LC-0001-DS6.35X5.08 |

| Ds6.35x12.7 | 40 | 0.005 | DST-JFRM-LC-0001-DS6.35X12.7 |

| Ds6.35x25.4 | 40 | 0.005 | DST-JFRM-LC-0001-DS6.35X25.4 |

| Ds8x10 | 75 | 0.01 | DST-JFRM-LC-0001-DS8X10 |

| Ds8x15 | 75 | 0.01 | DST-JFRM-LC-0001-DS8X15 |

| Ds10x12 | 75 | 0.01 | DST-JFRM-LC-0001-DS10X12 |

| Ds10x25 | 75 | 0.01 | DST-JFRM-LC-0001-DS10X25 |

| Ds10x50 | 75 | 0.01 | DST-JFRM-LC-0001-DS10X50 |

| Ds12x5 | 125 | 0.03 | DST-JFRM-LC-0001-DS12X25 |

| Ds12x25 | 125 | 0.03 | DST-JFRM-LC-0001-DS12X5 |

| Ds14x25 | 125 | 0.03 | DST-JFRM-LC-0001-DS14X25 |

| Ds14x30 | 125 | 0.03 | DST-JFRM-LC-0001-DS14X30 |

| Ds14x40.6 | 125 | 0.03 | DST-JFRM-LC-0001-DS14X40.6 |

dryspin trapezoidal lead screw nut

| Thread single start | Max. static axial F [N] | max. idling torque (with O-ring) from [Nm] | Part number |

|---|---|---|---|

| Tr8x1.5 | 75 | 0.01-0.03 | JFRM-LC-0001-TR8X1.5 |

| Tr10x2 | 75 | 0.01-0.03 | JFRM-LC-0001-TR10X2 |

| Tr10x3 | 75 | 0.01-0.03 | JFRM-LC-0001-TR10X3 |

| Tr12x3 | 125 | 0.06 | JFRM-LC-0001-TR12X3 |

| Tr12x4 | 125 | 0.08 | JFRM-LC-0001-TR14X3 |

| Tr14x4 | 125 | 0.08 | JFRM-LC-0001-TR14X4 |

dryspin trapezoidal lead screw nut multi start

| Thread multi start | |||

|---|---|---|---|

| Tr06x2P1 | 40 | 0.01-0.03 | JFRM-LC-0001-TR06X2P1 |

| Tr12x6P3 | 125 | 0.06 | JFRM-LC-0001-TR12X6P3 |

The anti-backlash lead screw nut

Lead screw drives can generally produce noise and vibrations. In particular, long lead screws and great travel distances can cause self-induced vibrations in the sliding system. Due to their good sliding properties, lead screw nuts made from the tribologically optimised iglidur materials tend to develop significantly less noise than conventional plastics or metals, such as bronze or brass.

To reduce noise, a preloading mechanism is also an effective measure in addition to the right choice of material. In the case of the AB lead screw nut, an elastomer ring applies a force on an insert with a matching thread, which is pressed into the threads of the lead screw. It is important that this pretension is not present over the entire length and not all around. This ensures low axial clearance only in a small range. The functional principle of this lead screw nut differs significantly from that of the zero-backlash lead screw nut.

- Reduction of noise and vibrations

- For trapezoidal threads up to a thread diameter of 24mm

- Cylindrical and flange lead screw nuts

- Thread direction: RH and LH

- Material: iglidur J and iglidur R

Anti-backlash lead screw nut: Technical data

Cylindrical trapezoidal lead screw nut

| Thread | Effective support surface [mm2] | Max. static axial F [N] | Part number |

|---|---|---|---|

| Tr8x1.5 | 228 | 683 | JSRM-AB-2220-TR8X1.5 |

| Tr10x2 | 283 | 848 | JSRM-AB-2220-TR10X2 |

| Tr12x3 | 396 | 1.188 | JSRM-AB-2220-TR12X3 |

| Tr16x4 | 704 | 2,111 | JSRM-AB-2220-TR16X4 |

| Tr18x4 | 905 | 2.714 | JSRM-AB-2220-TR18X4 |

| Tr20x4 | 1,131 | 3.393 | JSRM-AB-2220-TR20X4 |

| Tr24x5 | 1.621 | 4.863 | JSRM-AB-2220-TR24X5 |

Trapezoidal lead screw nut with flange

| Thread iglidur® J | Effective support surface [mm2] | Max. static axial F [N] | Part number |

|---|---|---|---|

| Tr10x2 | 353 | 1,060 | JFRM-AB-2220-TR10X2 |

| Tr10x3 | 334 | 1,001 | JFRM-AB-2220-TR10X3 |

| Tr12x3 | 396 | 1.188 | JFRM-AB-2220-TR12X3 |

| Tr14x4 | 471 | 1,414 | JFRM-AB-2220-TR14X4 |

| Tr16x2 | 613 | 1,838 | JFRM-AB-2220-TR16X2 |

| Tr16x4 | 704 | 2,111 | JFRM-AB-2220-TR16X4 |

| Tr18x4 | 905 | 2.714 | JFRM-AB-2220-TR18X4 |

| Tr20x4 | 1,131 | 3.393 | JFRM-AB-2220-TR20X4 |

| Tr24x5 | 1.621 | 4.863 | JFRM-AB-2220-TR24X5 |

Cylindrical trapezoidal lead screw nut iglidur R

| Thread iglidur® R | Effective support surface [mm2] | Max. static axial F [N] | Part number |

|---|---|---|---|

| Tr10x2 | 283 | 424 | RSRM-AB-2220-TR10X2 |

| Tr12x3 | 396 | 594 | RSRM-AB-2220-TR12X3 |

| Tr16x4 | 704 | 1,056 | RSRM-AB-2220-TR16X4 |

| Tr18x4 | 905 | 1,357 | RSRM-AB-2220-TR18X4 |

| Tr20x4 | 1,131 | 1,696 | RSRM-AB-2220-TR20X4 |

| Tr24x5 | 1.621 | 2.432 | RSRM-AB-2220-TR24X5 |

Trapezoidal lead screw nut iglidur R

| Thread iglidur® R | Effective support surface [mm2] | Max. static axial F [N] | Part number |

|---|---|---|---|

| Tr10x2 | 353 | 530 | RFRM-AB-2220-TR10X2 |

| Tr10x3 | 334 | 501 | RFRM-AB-2220-TR10X3 |

| Tr12x3 | 396 | 594 | RFRM-AB-2220-TR12X3 |

| Tr14x4 | 471 | 707 | RFRM-AB-2220-TR14X4 |

| Tr16x2 | 613 | 919 | RFRM-AB-2220-TR16X2 |

| Tr16x4 | 704 | 1,056 | RFRM-AB-2220-TR16X4 |

| Tr18x4 | 905 | 1,357 | RFRM-AB-2220-TR18X4 |

| Tr20x4 | 1,131 | 1,696 | RFRM-AB-2220-TR20X4 |

| Tr24x5 | 1.621 | 2.432 | RFRM-AB-2220-TR24X5 |

Consulting

I look forward to answering your questions

J. & E. Papadopoulos S.A.+30 210 4113133Write e-mail

Shipping and consultation

In person:

Monday to Friday from 7 am - 17 pm.

Saturdays from 8 am- 12 pm.

Online:

24h

WhatsApp-Service:

Montag – Freitag: 8 – 16 Uhr