Change Language :

Conveyor rollers

With the ever-increasing requirements in conveyor technology, especially in material handling, the demands on the materials used for the conveyed goods are also increasing. With increasing speed, one of the most important elements in drive technology must function reliably: the bearing. Conveyor rollers are available in a wide variety of designs: Driven conveyor rollers made of steel, stainless steel, aluminium or plastic. They are used to create a rolling contact between the conveyor frame and the conveyor belt.

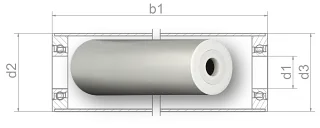

Basically, conveyor rollers consist of a support axle, which is enclosed by a support sleeve, and deep groove ball bearings with flanges as end caps. Our conveyor rollers for roller conveyors can be used flexibly and can be fitted with different deep groove ball bearings depending on requirements. In addition to conveyor technology, xiros conveyor rollers with ball bearings are used in labelling technology, packaging and the food industry, where they can also take on the function of a return roller.

What are the advantages of our conveyor roller?

Where can I buy the conveyor roller?

configure conveyor roller online

With the online tool for configuring xiros conveyor rollers, you will receive the right product in just a few steps after entering your requirements. Simply enter the outerand inner diameter, determine the load and load case as well as the temperature of the application.

Choosing the right conveyor roller

Where are conveyor rollers used?

Smooth running and 100% lubrication-free

Instead of metal solutions made of steel, which were too heavy and had to be lubricated, this labelling machine uses plastic ball bearings in up to 36 conveyor rollers. In this system, they ensure film transport in the form of film deflection. This has increased service life and reduced maintenance costs. To date, the plastic ball bearings have ensured smooth running of the conveyor rollers and uninterrupted operation of the system.

Consulting

I look forward to answering your questions

J. & E. Papadopoulos S.A.+30 210 4113133Write e-mail

Shipping and consultation

In person:

Monday to Friday from 7 am - 17 pm.

Saturdays from 8 am- 12 pm.

Online:

24h

WhatsApp-Service:

Montag – Freitag: 8 – 16 Uhr